Solar power generation is drawing attention as a system that utilizes reusable energy.

Toy Factory conducted a system development for this evolutional equipment for campervans and pioneered the new era of vehicle mounted solar systems.

The base for solar panels, developed by original molding was awarded “Good Design Award” in 2009 by the Ministry of Economic, Trade and Industry of Japan.

The solar panel, realized through the first in the industry joint development with Sharp Corporation, is the product dedicated exclusively for Toy Factory vehicles with basic specifications that include "Anti-Salt Damage," "Anti-Scattering," "Enhancement for Wind-Pressure," "Earthquake Resistance and Durability," and "Maximum Operating Power of 220W while Driving."

The panel is protected from rust and corrosion in salt damage prone areas by using special coatings, to offer stable quality and performance that last over many years.

Measures have been taken with the solar panel of Toy Factory to make them scatter resistant, by minimizing the extent of scattering that occurs from unforeseen problems and objects falling on the panel.

The product has attained a wind pressure load resistance of 2,940 Pa. This covers driving with the product mounted on a vehicle driving at 120 km/hr with wind velocity of 33 m/sec.

The tests were conducted repeatedly to improve the earthquake resistance and durability performance of the product. The performance exceeds the relevant international standards.

Placed on the roof, it achieves a modular conversion rate of 19.1%. Highly efficient modules are a part of the basic specifications for solar panels dedicated for Toy Factory vehicles.

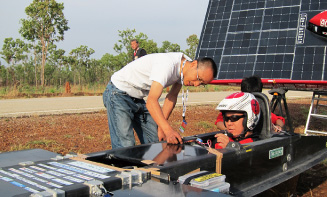

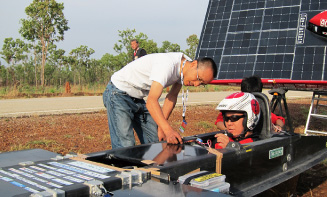

October 2011, 37 teams representing 21 countries participated in the world's largest solar car race, "The World Solar Challenge 2011" held in Australia. Toy Factory participated as a supporter for "Team OKINAWA" consisting of students of Nanbu Technical High School of Okinawa and drove with them throughout the entire course of the race. We took on the challenge of crossing Australia over a range of 3,000 km, which was the first for a van conversion camper produced in Japan. While we provided a complete backup for the race participants, we also considered this a perfect opportunity for conducting our field test relating to thermal insulation performance that we have been pursuing since the foundation of the company, as well as the utilization of solar energy. We collected information from instruments set up in our command vehicle “BADEN,” over a period of 20 days. The result of the race was the team arrived in the 13th place, competing head to head against Stanford University to the end, as they bravely took on powerful universities around the world. High school students from Okinawa have sensationally proven that the vehicle they created was indeed good enough to stand against others in an international racing competition. Toy Factory collected a large amount of field data and with the President Fujii himself drove the vehicle during the race, which allowed us to have precious experience that will become useful for the development of our product. We achieved good results. Please expect to see more projects and new products from Toy Factory in the future.

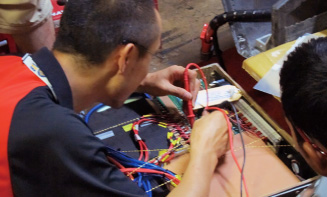

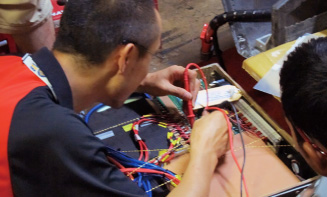

Driving data of vibration that may potentially occur while driving a vehicle was collected by taking measurements of acceleration that applies to the two location of a solar panel, namely the central part and on the corners, while the vehicle was driven by our staff members and experts of the field, on ordinary roads, expressways and across railroad crossings, through gravel roads, offroads and a variety of locations. Vibrations were also applied directly to perform load durability test with the vehicle loaded on vibration test equipment.

The experiment was conducted for the range equivalent to the driving distance of 118,500 km, which would make it three times around the earth. The solar panel dedicated for campervans emerged from the first in the world joint development conducted with Sharp Corporation, which was conducted based on such verification results.

Far Stricter Than Global Standards - Quality Tests at Sharp

Far Stricter Than Global Standards - Quality Tests at Sharp

Study sessions were held in collaboration with Sharp in 2012 and 2015, with participation of all staff members at the Toy Factory (Head Office and Okinawa Factory).

Studies that started from the history of the solar panel through to the outlook for the future, as well as presentations on products that may be installed in campervans from Toy Factory were provided.

Scenes from the study sessions, as well as our activities relating to solar power were introduced by corporate newsletter at Sharp.